A-A-52130

2.2 Construction.

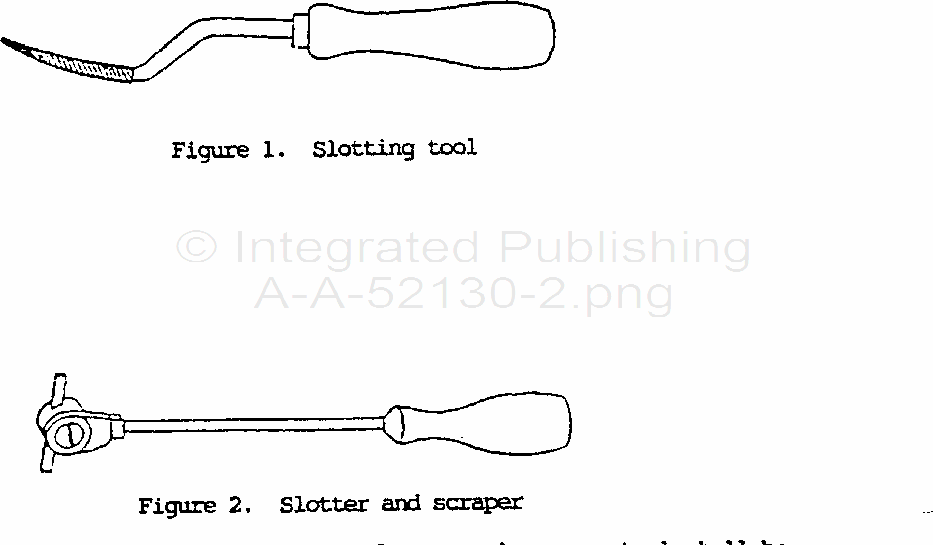

2.2.1 Type D. Slotting tools shall conform to figure 1 with an overall length of 10 inches ± 1 inch. The working end shall be a curved, 3 edge, single end draw cut type file made of a high grade steel, and hardened to a minimum of Rockwell C 60.

2.2.2 Type E. Slotter and scraper tools shall conform to figure 2 with a minimum overall length of 6-1/4 inches. The slotter and scraper tools shall have an adjustable head permitting rotation of the removable cutting bit, contained therein, to any angle. The cutting bit, hardened within the range of Rockwell C 60 to C 63, shall be sharpened for “U” cutting on one end, and for “V” cutting on the other.

[IMAGE HERE]

2.3 Hardness. The slotting tool and the slotter and scraper tool shall be heat treated to attain the hardnesses specified, when tested per ASTM E 18.

2.4 Handles. The type D slotting tool and the type E slotter and scraper tool handles shall be made of wood, metal, or plastic and shaped to provide a good hand grip. Plastic handles, when furnished, shall be unbreakable under ordinary service conditions.

2.5 Marking for identification. The tools shall be permanently and legibly marked with the manufacturer’s name or readily identifiable trademark in accordance with the manufacturer’s standard commercial practice.

2.6 Finish. The tools shall be finished in accordance with the manufacturer’s standard commercial practice.

2.7 Workmanship. The tools shall be free of rust, burrs, sharp edges (except cutting edges), bent or fractured components. Wood handles, when applicable, shall be free of splinters or knots.

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business